Portasonic® PLUS

System Integration, Data Logging, and Export

The unit is equipped with 4 MB of onboard memory, allowing users to store measurement data directly in the device. Logged data can be extracted later using the micro‑USB port, or measurements can be streamed live to a computer via the same connection.

Recording flow data at a standard frequency of 1 Hz provides a reliable performance history and supports trend analysis, safety verification, and system documentation.

The clamp‑on sensor design allows the device to be installed on most pipe types without cutting, drilling, or interrupting flow. It can be used for long‑term monitoring at a fixed location or easily moved to another site when needed, offering both permanent and portable operational flexibility.

If you want to learn more about how this instrument can support your process efficiency and safety, contact the sales team for additional guidance.

Three Flow Measurement Formats

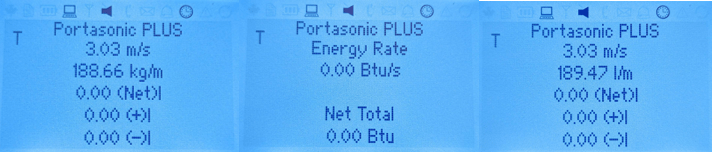

To maximise the usefulness of recorded data, the device can present flow rate in three different metrics:

Volumetric Flow Rate

Displayed in litres per minute or gallons per minute. This represents the volume of liquid moving through a pipe and is widely used in industrial applications.

Mass Flow Rate

Shown in kilograms per minute or pounds per minute. The device calculates this using the liquid’s density and the measured flow rate. Commonly applied in processes such as fuel loading, unloading, or transfer operations.

Thermal/Energy Flow Rate

Expressed in kilowatts per hour or British Thermal Units (BTU) per second. This metric describes the amount of heat energy carried by the flowing medium and is often used for heating, cooling, or thermal management systems.

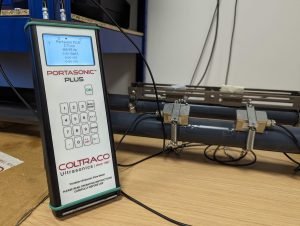

Handheld Ultrasonic Flow Meter with Data Logging

This portable transit‑time ultrasonic flow meter is engineered to accurately measure the flow rate inside pipes while also storing and exporting measurement data. It features a configurable built‑in database that supports a wide range of pipe materials and liquid types, enabling flexible setup for many different applications. Its adaptability makes it a practical solution for both general monitoring and specialized installations.

Part No.: 2618949-PSOPLUS

CAGE Code: KD983 – COLTRACO LIMITED

Overview

High‑Accuracy Flow Measurement

This ultrasonic flow meter delivers measurements with an accuracy of approximately ±0.5% of the actual flow value. Its performance is supported by several advanced features:

Configurable material and fluid library – Includes an extensive selection of fluid types and pipe materials for flexible setup.

Integrated ultrasonic thickness measurement – Enables users to check pipe wall thickness and verify that the installation meets safety requirements.

Built‑in signal oscilloscope – Assists with sensor diagnostics and helps confirm the quality of the measurement signal.

Multiple measurement modes – Three available methods allow the device to accommodate pipes of various sizes (details available in the product brochure).

Two sensor configurations – Designed to suit different pipe diameters, with waterproof sensor versions also offered.

Portasonic® CALCULATOR

Calculate Internal Pipe Pressure from External Flow Data

The Portasonic® CALCULATOR is the first tool engineered to estimate internal pipe pressure using non‑invasive, externally measured flow information. It enables pressure assessment without physically accessing the fluid or opening the pipework.

Designed to operate alongside the Portasonic® PLUS Ultrasonic Flow Meter, it complements one of the industry’s most trusted non‑contact flow measurement instruments—widely used across maintenance, inspection, and monitoring applications.

Technical Specifications

Dimensions:

220 × 85 × 22 mm (L × W × D)

Weight:

434 g (with batteries)

Pipe Compatibility

Standard Sensor (DM10):

DN15 – DN700 (½″ – 28″)

Large Sensor (DS10):

DN25 – DN2500 (1″ – 98″)

Performance

Accuracy: ±0.5% of true flow rate

Resolution: 0.25 mm/s

Repeatability: 0.15% of measured value

Flow Velocity Range: 0.01 – 25 m/s

Turn‑Down Ratio: 1:100

Measurement Rate: 1 Hz (standard)

Certifications

UKCA

CE

Manufacturer certified to ISO 9001:2015 and ISO 14001

Optional ISO 17025 calibration certification

Measurement Types

Flow Velocity

Volumetric Flow Rate

Mass Flow Rate

Energy/Heat Flow Rate

Total Volume

Total Mass

Total Energy

Display

128 × 68 backlit LCD

Features

4 MB internal data storage with Micro‑USB export

Built‑in thickness gauge (2–20 mm range)

Integrated signal oscilloscope for positioning and diagnostics

Power

1 × 9V PP3 battery (up to 12 hours continuous use)

Continuous power option via Micro‑USB

Operating Temperatures

Main Unit: −10°C to +65°C (14°F to 149°F)

Sensors: −20°C to +150°C (−4°F to +302°F)

Sensor Dimensions

Standard Sensor (DM10):

40 × 20 × 25 mm (L × W × D)

Large Sensor (DS10):

60 × 30 × 35 mm (L × W × D)

Cable:

1.5 m BNC coaxial (longer options available)

IP Rating

Main Unit: IP65

Sensors: IP66 (IP68 option available)

Warranty & Support

Main Unit: 3 years

Sensors: 1 year

Technical Support: Lifetime of the unit

What’s Included

Main Portasonic® PLUS Device – The central handheld unit.

Pair of DM10 Standard Sensors – Suitable for pipe sizes from DN15 up to DN700.

Beaded Chain Mounting Clamps – Used to secure the sensors in place on the pipe surface.

10 mm Ultrasonic Thickness Probe – For measuring pipe wall thickness prior to flow measurement.

Ultrasonic Couplant Gel – Ensures strong acoustic contact between sensors and pipe.

Measuring Tape – Helps position the sensors at the correct spacing.

User Guide – Instructions on operating the device.

Installation Guide – Provides best‑practice advice for mounting sensors on different pipe types.

Calibration Certificate – Confirms the instrument’s performance and calibration at the time of shipment.

Durable Carry Case – Protects and organizes all supplied components.