Fire Suppression Monitoring with Ultrasonic Technology

Ultrasonic Liquid Level Indicators

-

Portalevel® IS

Choose for EX-Rating

Choose for testing in ATEX Zone 1 classified areas

Choose for testing in IECx classified areas

Choose for cylinders up to 400mm in diameter

-

MAX MARINE PLUS

12mm slimline extension rod sensor.

Choose for LIQUID/GAS readings

Choose for UL, RINA and ABS Type Approval.

Choose for cylinders up to 400mm in diameter.

-

Portamarine®

20mm standard extension rod sensor

Choose for cylinders up to 320mm in diameter

Choose for RINA Approved, IMO

SOLAS FSS compliant

Portasteele® CALCULATOR

Liquid Level to Weight Conversion Tool

This calculator is designed to work seamlessly with ultrasonic liquid level measurement devices. It converts the detected liquid level into an accurate weight estimate of the agent. All calculated values can be stored and exported, providing reliable documentation and traceability for future use.

Optimized for use with ultrasonic level indicators.

Part Number: CALC-007

CAGE Code: KD983 – Manufacturer: Coltraco Limited

Why Choose coltraco Ultrasonic Liquid Level Indicators for Fire Suppression?

Our ultrasonic technology offers a fast, safe, and non-invasive way to check fire suppression cylinders - no system shutdown, no heavy lifting, and no disruption. Each inspection takes about 30 seconds per cylinder, compared to 15 minutes with traditional weighing.

Benefits:

Regulatory-compliant alternative for monitoring cylinder contents.

High accuracy: ±1.5 mm.

Cost-effective: Saves time, labor, and avoids downtime.

Competitive pricing backed by our Price Promise.

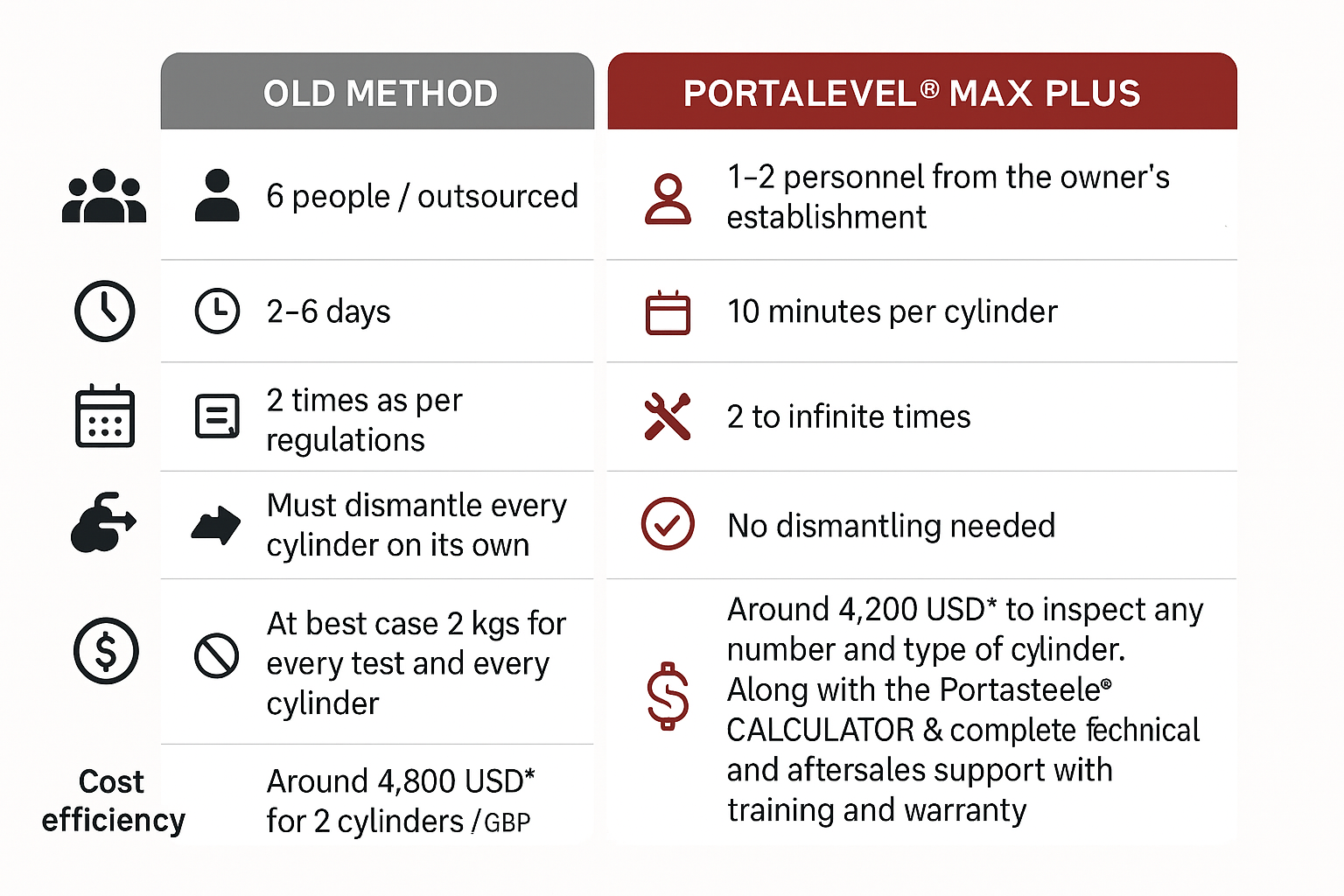

Ultrasonic vs. Traditional Approaches

Ultrasonic testing dramatically reduces inspection time and eliminates expenses tied to hydraulic carts and weighing scales. With accurate “GAS” or “LIQUID” readings, these devices minimize gas loss risks, cut replenishment costs, and enhance safety for personnel.

Key Benefits at a Glance

Lower labor requirements

Faster, simplified workflow

Improved traceability and compliance

Why Monitor Fire Suppression Systems?

Fixed fire suppression systems protect critical infrastructure and assets. They rely on high-pressure cylinders filled with agents like CO₂, FM-200™, NOVEC™ 1230, and Halons. Over time, cylinders can leak, so regulations require checks every 6 months to ensure proper agent levels.