Portasonic® Pro

Benefits of Non‑Invasive Ultrasonic Flow & Pressure Monitoring

Choosing clamp‑on ultrasonic transit‑time technology offers significant advantages over traditional inline flow meters:

Zero downtime and no pipe modifications: Installation does not require cutting, drilling, or interrupting the system.

No contact with the fluid: Eliminates contamination risk, pressure drops, and wear on internal components—resulting in lower maintenance costs and improved long‑term reliability.

Critical for safety: Understanding internal pipe pressure helps prevent failures, equipment damage, and potential hazards to surrounding personnel and infrastructure.

Core Features of the Portasonic® PRO

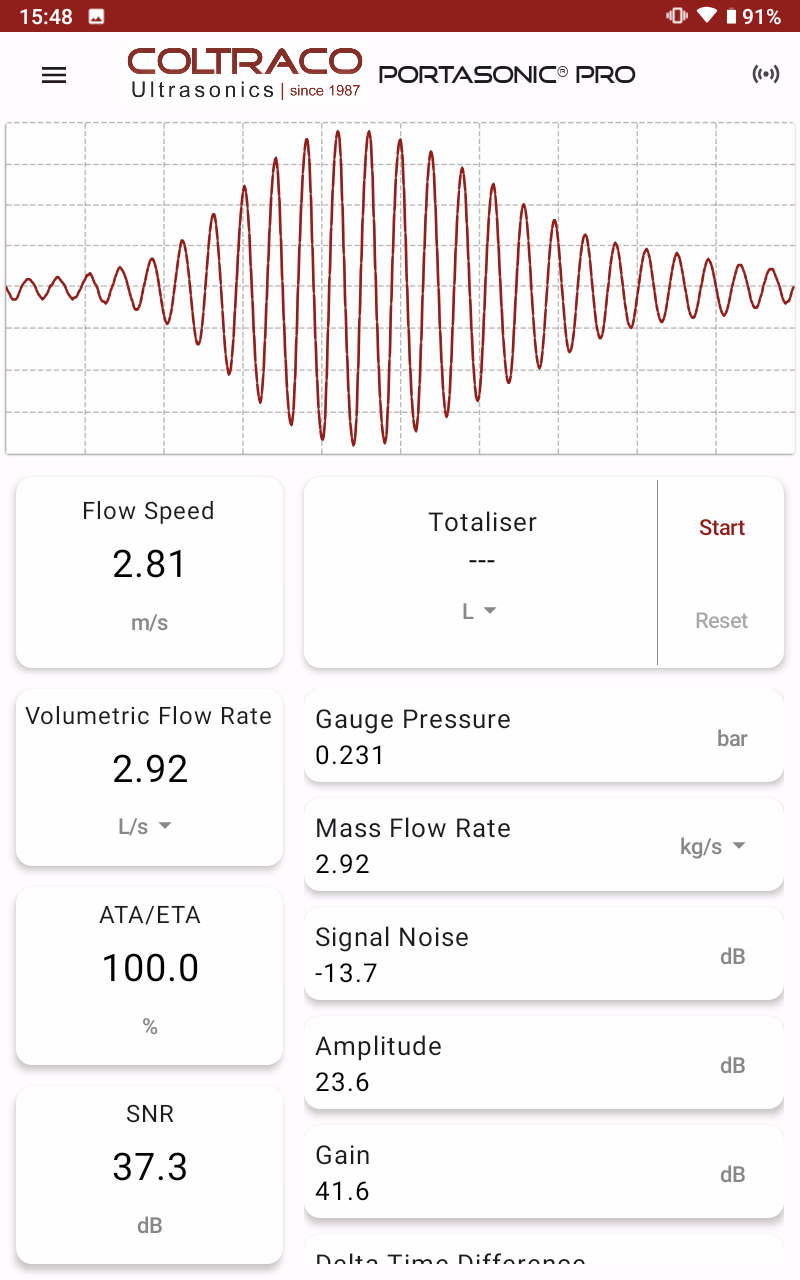

Integrated Portasonic® CALCULATOR: Enables real‑time pressure calculations directly on the device without the need for separate software.

Advanced data logging: Capable of storing millions of flow and pressure measurements for analysis and traceability.

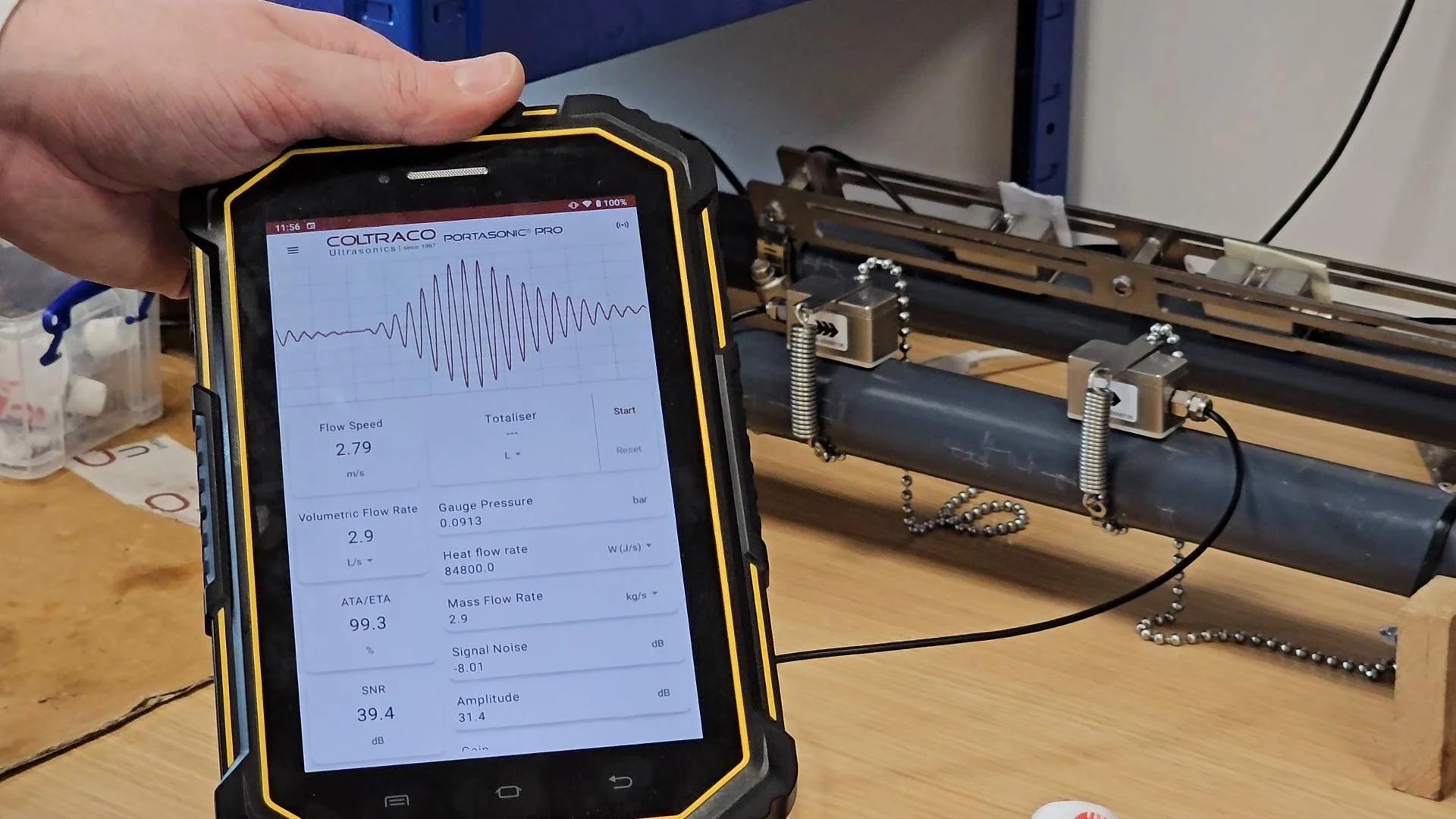

Heat‑flow calculations: Users can calculate thermal energy transfer by entering inlet and outlet temperatures.

Totaliser function: Tracks cumulative flow over time for long‑term monitoring and auditing.

Extensive material database: Includes more than 15 pipe materials and fluid options for broad compatibility.

Wide pipe size range: Supports pipe diameters up to 750 mm.

Enhanced user interface: A fully redesigned interface provides streamlined navigation and improved ease of use.

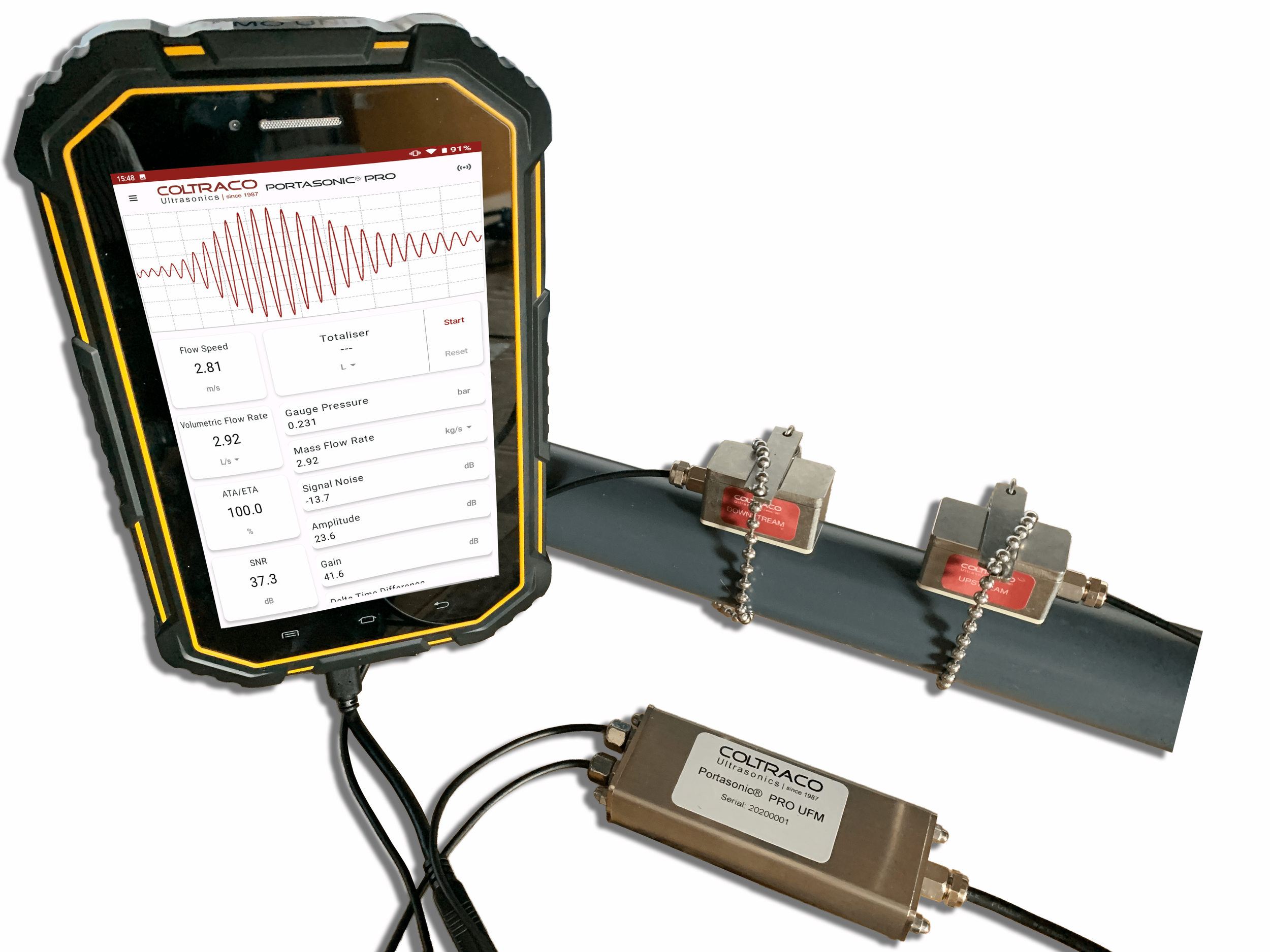

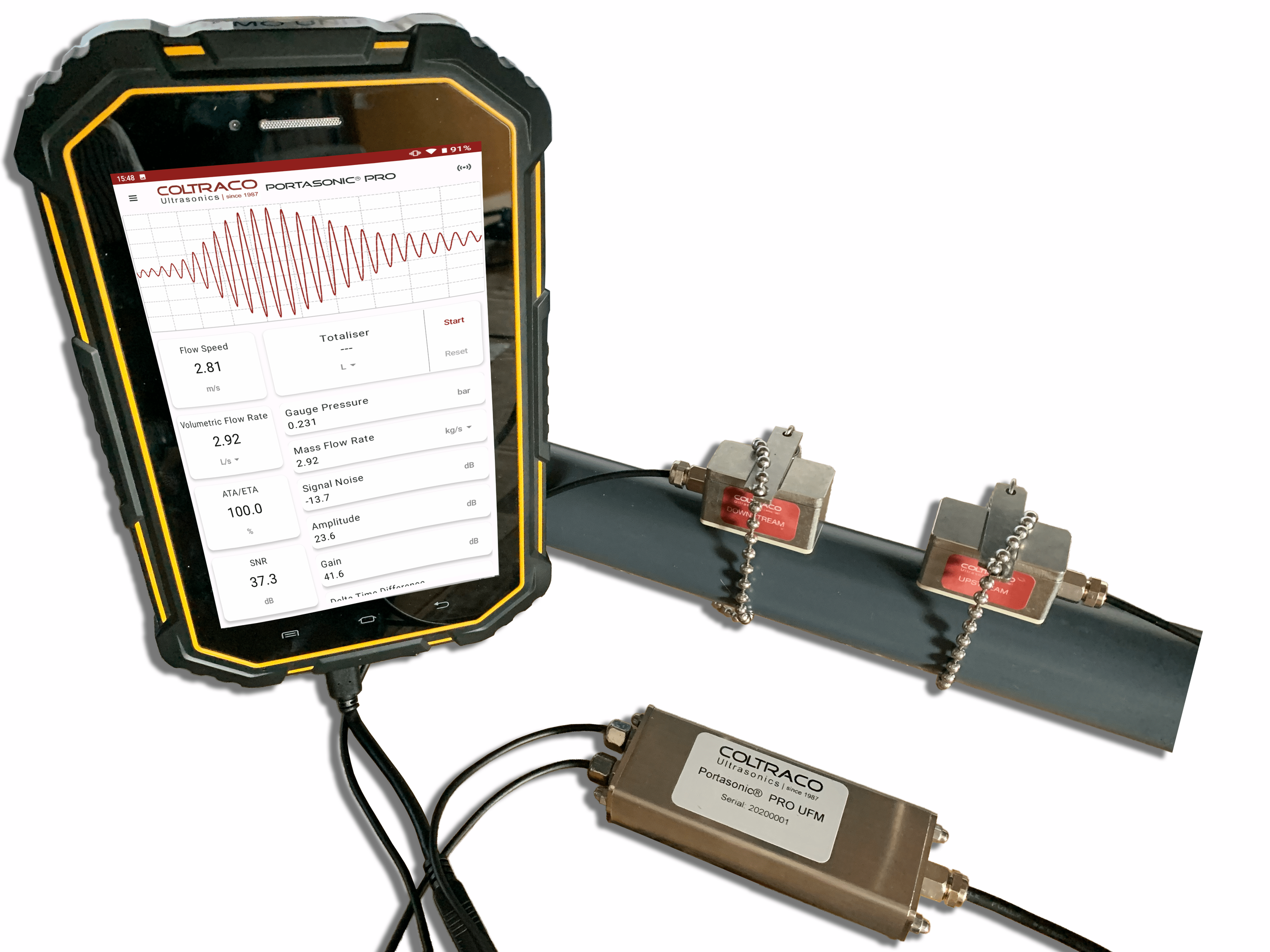

Handheld, Tablet‑Based Ultrasonic Clamp‑On Flow Meter with Pressure Calculation Software

The Portasonic® PRO is a portable, tablet‑operated ultrasonic flow meter designed for clamp‑on measurement and equipped with advanced software that estimates internal pipe pressure based solely on recorded flow data. By combining non‑intrusive flow monitoring with predictive pressure analysis, it brings together the capabilities of the Portasonic® flow meter and the Portasonic® Calculator. The result is the first device able to estimate internal pipe pressure using only external, non‑contact ultrasonic sensors.

Part No.: 2618949‑PSOPRO

CAGE Code: KD983 – COLTRACO LIMITED

Overview

Ultrasonic Clamp‑On Flow Meter with Integrated Pressure Calculation

The Portasonic® PRO unifies the functionality of a clamp‑on ultrasonic flow meter with built‑in software capable of estimating internal pipe pressure from external flow measurements. It merges the flow‑measurement capabilities of the Portasonic® with the predictive pressure tools of the Portasonic® CALCULATOR, creating a single instrument that can perform both tasks seamlessly.

Key Measurement Capabilities

High‑accuracy flow readings: Non‑invasive ultrasonic technology delivers liquid flow measurements with industry‑leading precision of around 0.5%.

Independently verified performance: Flow accuracy is tested and validated by an ISO 17025‑accredited laboratory for assurance of measurement quality.

Pressure estimation: When enabled, the device simultaneously displays both flow rate and the calculated internal pipe pressure.

Advanced calculation models: Pressure values are determined using empirical equations rooted in fluid dynamics, achieving approximately 5% estimation accuracy.

Material & fluid database: The system incorporates knowledge of more than 19 fluid types and over 23 pipe materials to ensure reliable pressure predictions across a broad range of applications.

Technical Specifications

Dimensions

• Tablet: 216 × 136 × 19 mm

• Processing Unit: 105 × 40 × 21 mm

• Sensors (DM10): 40 × 20 × 25 mm

Weight

• Tablet: 558 g

• Processing Unit + Sensors: 400 g

Pipe Diameter Range

• DN15 – DN750 (½″ – 30″)

• Compatible with 12+ pipe materials

Liquid Types

• 14+ preset fluids (e.g., water, petrol, fuel oil)

Accuracy

• Flow: ±0.5%

• Pressure: ±5%

Flow Velocity

• 0.01 – 25 m/s

Resolution

• 0.25 mm/s

Repeatability

• 0.15% of measured value

Battery

• 8000 mAh Li‑ion

• ~10 hours continuous use

• ~200 hours standby

Measurement Rate

• 1 Hz

Measurement Units

• Flow velocity

• Volumetric flow rate

• Mass flow rate

• Energy/heat flow

• Total volume

• Pressure

Sensor Material

• Housing: Stainless steel

• Face: PEEK

Cable Length

• 1.5 m (longer available)

IP Rating

• Tablet: IP67

• Sensors: IP66

CPU

• MT6762 Cortex‑A53, octa‑core, 2.0 GHz

• GPU: PowerVR GE8320, 650 MHz

Operating System

• Android 9.0

Battery

• 8000 mAh Li‑ion

• ~10 hours continuous use

• ~200 hours standby

Data Transfer

• USB Type‑C

Display

• 7" HD IPS touchscreen

• 1280 × 800 px

Memory

• RAM: 4 GB

• Storage: 64 GB

• Can store millions of flow & pressure logs

Cameras

• Front: 2 MP

• Rear: 13 MP with flashlight

Sensors Included

• Geomagnetic

• Light

• Proximity

• Gravity

• Gyroscope

Certifications

• CE

• Manufacturer certified to ISO 9001:2015 & ISO 14001

Warranty

• Main Unit: 3 years

• Sensors: 1 year

• Lifetime technical support

What’s Included

Portasonic® PRO 7” Tablet A rugged, handheld 7‑inch touchscreen tablet with a rechargeable power supply.

Processing Unit with DM10 Standard Sensor Pair (DN15 – DN700) Compact ultrasonic sensors paired with a processing module for clamp‑on flow measurement.

Two Beaded Chain Clamps Metal chain clamps designed for quick and secure mounting of the sensors onto the pipe.

Measuring Tape Used to set the correct spacing between sensors during installation.

Ultrasonic Couplant Ensures reliable acoustic contact between the sensor faces and the pipe surface.

USB‑C to USB‑A Adapter Allows direct sensor connection to the tablet and supports plugging in a USB drive for data export.

USB‑C Cable For charging the tablet and transferring data.

Power Adapter Supplies power for charging the tablet.

USB Drive Provided for storing and exporting measurement data.

User Manual Contains operating instructions and details on device functionality.

Installation Guide Offers step‑by‑step guidance for mounting and setting up the sensors on the pipe.

Calibration Certificate Confirms the device has been tested and calibrated prior to shipment.

Durable Carry Case Protects the equipment and allows easy transportation.

Ultrasonic Liquid Level Indicators

-

Portalevel® IS

Choose for EX-Rating

Choose for testing in ATEX Zone 1 classified areas

Choose for testing in IECx classified areas

Choose for cylinders up to 400mm in diameter

-

MAX MARINE PLUS

12mm slimline extension rod sensor.

Choose for LIQUID/GAS readings

Choose for UL, RINA and ABS Type Approval.

Choose for cylinders up to 400mm in diameter.

-

Portamarine®

20mm standard extension rod sensor

Choose for cylinders up to 320mm in diameter

Choose for RINA Approved, IMO

SOLAS FSS compliant