Cleaner air, fresher provisions, safer galleys — air purification built for life at sea

Cut food waste, improve crew health, and lower galley fire risk with Jimco MAC500/MAC500s air purification and KPC kitchen pollution control—proven in maritime cooling rooms and crew areas.

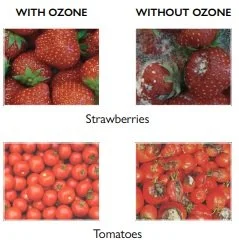

Reduce food waste and extend shelf life

Up to ~14 days longer for fruit & vegetables in cold stores, through UV‑C/ozone that degrades ethylene and suppresses fungi and bacteria. Third‑party testing shows 1.5–2.0% ethylene decay per hour in a 20 m³ room; shipboard references report week‑plus extension and rapid payback.

Safer, cleaner galleys with lower maintenance

Kitchen Pollution Control (KPC) breaks down grease and odor in exhaust air, reducing duct cleaning and fire risk. Documented case: no duct cleaning or carbon‑filter change since 2018 and ~USD 5,000 annual saving on filters alone.

Healthier indoor air for crew—

safe 24/7 in occupied spaces

Continuously reduces bacteria, viruses, mold and odors without producing NOx; recommended coverage up to 60 m³ per unit. Independent lab data (TBC/TFC) shows substantial microbial reduction within 60 minutes. Ideal for mess rooms, cabins, bridge and clinics.

jimco increases the awareness of environmentally friendly solutions and accelerates their implementation thus striving to make the world chemical-free without compromising the result.

REFERENCE FROM CONTAINER SHIP which has had MAC500s UV-C installed for the 3 years in the cooling room, where milk, fruit, vegetables and other temperature sensitive products are stored. The experience aboard with the MAC500s air cleanser is as follows: “We experience a significantly longer durability of fruit and vegetables, thus reduced waste goods. The smell is always comfortable in the cooling room.”

PEP/Captain

Contact Our Air purification expert

Jan Taudal

Sales Director

+45 3132 3647

jt@sepcotech.com